Solutions

VITALITY INDEX SUMMARY

Our Vitality Index is the percentage of new standard product revenues in the past five years, divided by the company's total revenues over the same period. New products exclude customized automation sales.

A Vitality Index is a common metric used to measure the effectiveness of a company's R&D innovation efforts. A high Vitality Index indicates that a company is effectively using its R&D resources to develop new products that are driving revenue growth. As a leader in welding technology and safety, our newest products are designed to make a positive impact, including automation products and enhanced software solutions. We consider our customers' sustainability goals in our product offerings, and strive to improve product material and energy efficiency, as well as safety. Many of our new products also deliver sustainability benefits. Several are highlighted below.

Measuring Progress with Life Cycle Analysis

Widely considered the gold standard for product sustainability assessments, the environmental footprint tool Life Cycle Assessment (LCA) considers the entire lifecycle of a product across a variety of environmental indicators such as carbon footprint, energy consumption, smog formation, ozone depletion and eutrophication. LCA analysis also considers product functionality to better enable comparability.

It is through this life cycle lens that we embed sustainability features in products throughout our broad solutions portfolio. When evaluating our products, we take into account the entire life cycle, which includes assessing attributes outside our operational control. In 2024, we began to formalize our life cycle focus by using an LCA tool in-house, which will better enable us to uncover parts of the life cycle that can be improved. Our intent is also to use LCAs to produce Environmental Product Declarations (EPDs) for our customers, providing us with a standardized and transparent way to communicate the environmental impact of our products. The EPDs will be peer-reviewed against a variety of international standards to ensure their credibility. We anticipate the first EPDs to be issued in 2025.

| Cradle-to-Gate LCA of Carbofil 1 Welding Wire-MIG | |

|---|---|

| Company Name | Lincoln Electric Holdings Inc. |

| Product Name | Carbofil 1 Welding Wire-MIG |

| Product Description | Carbofil 1 is a coppered welding wire used for general applications in both single- and multipass weld-ing. Espesially suited for sheet metal applications where smooth weld beads are required. |

| Declared Unit | 1 kg of finished product |

| LCA Software + Version | LCA for Experts (LCA FE) v10.9 |

| Life Cycle Impact Assessment method | Base on EN15804+A2 (Environment Footprint 3.1 [EF 3.1]) and ISO 21930 (TRACI 2.1, IPCC AR6) |

Automation: Driving a Cleantech Future

Lincoln Electric continues to develop an array of equipment and systems to remove inconsistencies from the welding process and maximize safety and efficiency. Our automation story is one of constant innovation, with the goal of providing industry-leading tools suitable for manufacturers around the world. Lincoln Electric's unparalleled combination of experience, expertise and customer support gets automation processes online quickly and successfully.

Our Offerings:

- Collaborative robotics

- Mechanized equipment

- Robotic laser systems

- Automated positioners

- Spray and die casting/foundry/forging equipment

- Automated material handling

- Robotic welding systems

- Robotic grinding systems

- Automated cutting systems

Automation Acquisition : Inrotech

In 2024, Lincoln Electric advanced our investment in clean technology through the acquisition of Inrotech, a company that is revolutionizing shipbuilding, offshore, renewables and heavy welding industries with innovative mobile welding robots. Inrotech developed the software that integrates the welding machine with the robotic arm, as well as sensing and scanning technology. The welding robot can automatically identify objects that need to be welded, no longer requiring advanced programming or the transfer of CAD-drawings.

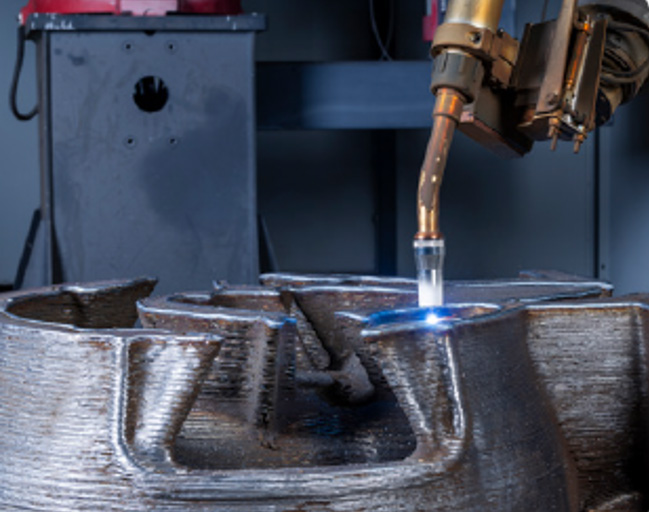

LINCOLN ELECTRIC ADDITIVE SOLUTIONS

MAKES BIG PARTS IN LESS TIME

Lincoln Electric Additive Solutions gives your business a big advantage over castings, forgings and other traditional manufacturing processes with the fast delivery of new and replacement parts and tooling.

With the largest 3D metal printing capacity in North America, we can expedite production for large industrial parts for your application and industry.

We continue to support industry needs for complex or large metal components. In 2024, new additive manufacturing cells at our facility allowed us to increase our capabilities to 3D print metal components. Our additive technology significantly reduces manufacturing lead times, shortens supply chains and enables design enhancements that may not be possible with traditional manufacturing methods.