WATER MANAGEMENT

Water is an important natural resource and we acknowledge our responsibility to manage water use carefully. Water is predominantly used in our consumable manufacturing processes. We monitor and measure absolute water use and water intensity (cubic meters of water used per hour worked). We have focused our water management initiatives on reducing water use and our reliance on freshwater.

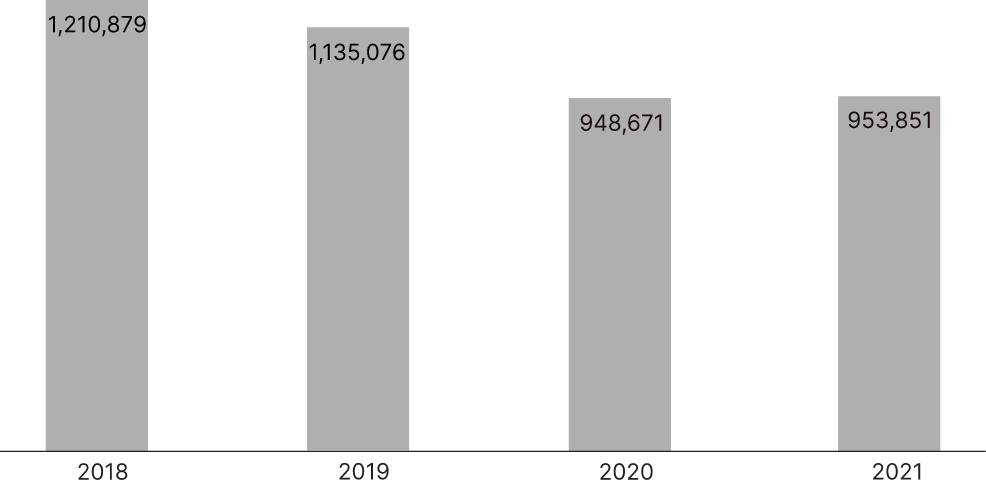

- In 2021, we achieved a 21% reduction or 953,851 cubic meters compared to our 2018 baseline. This performance exceeds our 2025 target reduction of 14%.

- We achieved this reduction by increasing the reuse and recycling rate of our water through improved wastewater treatment initiatives. We have also invested in manufacturing processes that have lower water requirements and achieved greater water efficiency.

- We currently have two “zero water discharge” facilities and several manufacturing facilities capture rainwater for reuse in manufacturing processes or for fire protection.

Water Usage (Cubic Meters)

REDUCTION from 2018 baseline to 2025

REDUCTION from 2018 baseline to 2021

Conserving Rainwater

To conserve water and reduce dependency on municipal water sources, our facility in Mexico City, Mexico, installed a 300,000-liter water retention cistern. The tank collects stormwater from the facility’s roof and parking lot, which is then filtered through a vortex separator. The facility’s plumbing was retooled to use this reclaimed water to supply the facility’s new fire protection system, cooling towers, scrubbers, and bathroom facilities. This project reduced the facility’s municipal water consumption by 25%.

Chemical Replacement Projects

Our Chattanooga, Tennessee facility has implemented several projects to reduce hazardous chemical waste, including the replacement of welding anti-spatter material, chemical cleaners, and coolant with less hazardous options. The facility also removed excess oil from waste coolant to avoid special waste handling and disposal for these materials.

Water Savings Through Data Monitoring

As part of a plant-wide implementation of interconnected smart sensors, our Chennai, India facility upgraded the pump and monitoring system of its cooling water towers. The upgrades enabled the towers to operate at a reduced, but stable flow rate. The system currently operates based on demand by using a variable drive pump. This has reduced water use and evaporative loss by over 300,000 gallons per year.

Chemical Plating Recovery

At our Mentor, Ohio facility, the team implemented a new filtration process to extend the useful life of their copper plating baths and reduce the frequency of chemical treatments before disposal. Significant water savings were achieved as fewer fresh plating baths are needed, and less water is used for the chemical treatment of spent plating baths. In 2021, the filtration process generated up to a 44% reduction in various plating and water treatment chemicals and reduced the facility’s water consumption by over 1.5 million gallons.