INNOVATIVE PRODUCT SOLUTIONS

WE ARE COMMITTED TO OPTIMIZING OUR PRODUCT OFFERINGS TO OUR CUSTOMERS WHILE LOWERING THE CARBON FOOTPRINT OF THESE PRODUCTS.

Inverter-Based Technology: Today, 85% of our welding machine product families are based on digital, inverter-based, technology. Inverter-based equipment reduces energy consumption by up to 26% compared to traditional equipment. To allow customers to determine their potential energy savings, we have created, through our website, an Inverter Energy Calculator that compares traditional equipment energy use to its inverter-based equivalent.

Customers will often upgrade a group of traditional equipment at one time to maintain consistency and realize significant energy savings. A typical inverter-based welding machine will use 1,526 kWh less energy per year to operate as compared with a traditional machine. Transitioning 5 traditional welding machines to 5 inverters will reduce GHG emissions at the same rate as taking one automobile off the road.

Portable and lightweight, when compared to traditional equipment, inverter-based welding power sources provide precise arc-starting capabilities and advanced output controls that allow welders to fine tune their welding output to desired parameters. The technology behind these units provides manufacturers with a power source that can perform high- and low-amperage flux-cored, stick, TIG and MIG welding, not to mention arc gouging and even CV submerged arc.

Today’s re-imagined inverter models deliver multi-process welding capabilities, offering faster arc response, smoother arc action and a more consistent bead appearance. This yields quality welds the first time around, eliminating the need to re-weld and also lessening the incidence of scrap.

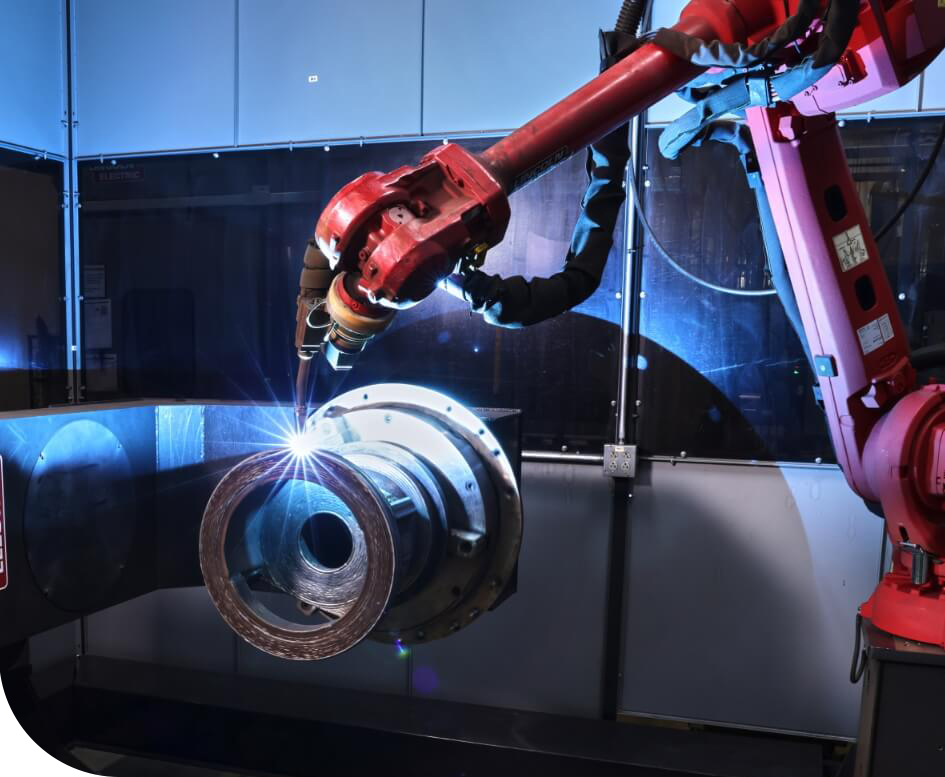

Automation: Robotic and mechanized arc welding and cutting solutions help address the acute shortage of skilled welders while improving weld quality, productivity, and safety for customers’ operations. We are the industry leader in providing automated solutions with the most comprehensive portfolio of solutions. Our new line of cobots (collaborative robots) enables small-to-medium-sized fabricators to realize the benefits of automation with easy drag-and- drop programming and versatility to support low volume and high mix operations.

Virtual Learning – VRTEX®: We are proud to offer comprehensive educational solutions to prepare the next generation of welders. Our VRTEX® virtual reality welding training simulators offer instructors and customers an innovative solution for more time- and cost-efficient training while reducing material use, waste, and energy intensity. Through virtual welding training, educators and customers administrating the welding courses can achieve:

- Lower training costs

- Improved student safety as virtual welding eliminates the use of metal (electrodes and coupons), sparks, heat, shielding gas, or weld fume removal

- Accelerated training times

- Reduced overall energy consumption by requiring less energy than a traditional welding machine, feeder, and fume control system

Additive Solutions: Our proprietary, large-scale metal 3D printing solution prints parts in less time. With the world’s largest platform of its kind, we help industrial, aerospace, and energy-sector customers source replacement parts, tooling, molds, and prototypes that measure up to eight feet and 8,000 pounds in weight.

Additive technology produces substantially less waste than traditional forging or milling operations, and projects are measured in weeks versus months. Additive manufacturing streamlines the prototyping process, doing away with unneeded prototypes that add cost, use more resources, and produce more waste.

Considerate Packaging Design

Just a decade ago, our Cleveland operations offered custom packaging solutions for our welding consumables. While the variety of packaging solutions added shelf appeal, the various designs added waste and cost. Our product teams worked together to optimize our consumable packaging strategy, simplify our packaging options, and support our sustainability initiatives. These initiatives included encouraging customers to move to larger packaging options, consolidating packaging, and ensuring the use of recyclable material where possible.

We simultaneously optimized our packaging strategy for welding equipment - going from 45 different packaging options down to just five. This not only increased production efficiency but it reduced inventory and waste. Current packaging for equipment and consumables is in brown Kraft, which has allowed us to reduce our reliance on plastic and bleaching processes while enhancing recyclability and reducing downstream waste for our customers.

Enhancing Circularity

Our vertically integrated manufacturing process allows us to reduce the life cycle impacts of our consumables and recycle and reuse many materials both inside and outside of our operations. Examples of how we close the loop, reduce raw material usage and impact product life within our consumables business include:

Stick electrodes: If stick electrode are manufactured outside our specifications, become damaged, or are returned under warranty, where possible, we remove coatings, clean and straighten the core rod material, and reuse this material in other manufacturing applications.

MIG wire: We look for opportunities to reduce packaging throughout our consumables line. This includes supplying customers with Accu-Pak® boxes instead of package configurations that are more difficult to recycle, and helping customers buy in bulk to reduce cardboard cartons, pallets, and spools.

SuperArc XLS: We recently introduced this novel MIG wire solution to provide enhanced corrosion-resistance properties that are especially useful in the automotive industry. Used in combination with our suggested welding process parameters, this solution produces a clean weld having improved paint adherence properties and corrosion-resistance. When used to join auto frames, chassis and suspension components, these properties can extend the life of the vehicle.

Submerged Arc Wire and Flux (SAW): As a strategic partner, we help our customers to reuse the flux in their submerged arc welding applications as repeatedly as possible. Our European facilities work relentlessly on optimizing grain size and hardness to enable more reuse cycles. It means less material is used in the end-to-end supply chain to perform the same job. A trial process is underway in our Cleveland operations to help our customers create a circular material flow. The customer ships its SAW slag, a by-product of the welding process, back to Lincoln Electric. Once received, we convert the raw material into new flux for the customer to use in manufacturing.